Top 10 Features of Advanced PP Woven Sack Making Machines

Introduction:

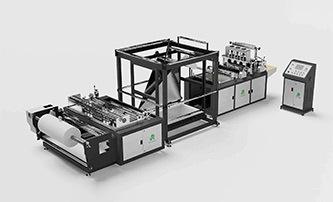

In the dynamic world of packaging, where innovation is the key to staying ahead, PP woven sack making machines have emerged as game-changers. These versatile machines have revolutionized the way companies approach packaging, offering efficiency, sustainability, and customization. In this blog post, we’ll delve into the top 10 features that make PP woven sack making machines a must-know for businesses aiming to elevate their packaging game, including advanced functionalities like liner insertion, hemming, PP Valvomatic, and inline four-color printing.

High-Speed Production: One of the standout features of PP woven sack making machines is their ability to deliver high-speed production. These machines can churn out a significant volume of woven sacks in a relatively short period, ensuring that businesses can meet demanding production schedules and fulfill market demands promptly.

Versatility in Materials: PP woven sack making machines are designed to work with a variety of materials, providing flexibility to businesses. Whether you’re working with virgin polypropylene or incorporating recycled materials for a sustainable edge, these machines can adapt to different raw materials, allowing for a broad spectrum of packaging possibilities.

Precision in Weaving Patterns: The intricate weaving patterns of PP woven sacks contribute to their strength and durability. Modern machines offer precise control over these weaving patterns, ensuring uniformity and consistency in the final product. This feature not only enhances the structural integrity of the sacks but also adds to their visual appeal.

Liner Insertion for Added Protection: Advanced PP woven sack making machines now come equipped with liner insertion capabilities. This feature adds an extra layer of protection to the contents of the sacks, making them suitable for a wide range of products, including those requiring moisture or contamination resistance.

Automation for Efficiency: Efficiency is a hallmark of PP woven sack making machines, thanks to advanced automation. From material feeding to cutting and stitching, these machines are equipped with automated systems that minimize manual intervention, reduce the risk of errors, and optimize the overall production process.

Customization Capabilities: Today’s businesses thrive on differentiation, and PP woven sack making machines empower them to stand out. These machines allow for customization in terms of size, color, and printing. From branding elements to specific size requirements, businesses can tailor their woven sacks to meet the unique needs of their products.

User-Friendly Controls: Operating a PP woven sack making machine is made easy with user-friendly controls. Intuitive interfaces and touchscreens provide operators with the ability to monitor and adjust various parameters, ensuring smooth operation and quick response to any changes in production requirements.

Hemming Machine for Seamless Edges: Achieving a professional finish is crucial in packaging, and the inclusion of a hemming machine in PP woven sack making adds to the aesthetic appeal. This feature ensures that the edges of the sacks are neatly hemmed, enhancing the overall look and feel of the final product.

Energy-Efficient Design: Sustainability is a key concern for businesses today, and PP woven sack making machines address this by incorporating energy-efficient design elements. From energy-saving motors to optimized production processes, these machines contribute to reducing the environmental footprint of packaging operations.

PP Valvomatic Machine and Inline Four-Color Printing: For businesses seeking to enhance functionality and branding simultaneously, PP Valvomatic machines and inline four-color printing are invaluable features. PP Valvomatic machines enable the inclusion of a valve for easy filling, while inline four-color printing allows for vibrant and detailed branding directly on the woven sacks.

Conclusion:

In the ever-evolving landscape of packaging, PP woven sack making machines stand out as technological marvels that drive efficiency, customization, and sustainability. As businesses navigate the challenges of modern packaging demands, understanding and harnessing the top 10 features, including liner insertion, hemming, PP Valvomatic, and inline four-color printing, can be the key to unlocking new possibilities and staying ahead in the competitive market.

Get Started with a Free Price Quote