Optimizing Paper Straw Production: Tips for Efficiency, Cost-Saving, and Minimizing Waste

Introduction:

The world is becoming increasingly environmentally conscious, so the demand for sustainable products is continuously growing. One such product is paper straws. Businesses across the world are making the switch from plastic to paper straws to reduce their environmental footprint, but the production of paper straws still poses some challenges.

In this blog, we’ll explore tips for optimizing the production of paper straw making machines to save costs. From choosing the right equipment to controlling the manufacturing process, we’ll take a closer look at the key strategies you can employ to enhance your production output while minimizing costs and waste. We’ll also examine how you can maintain the quality of your paper straws while meeting production targets with minimal disruption.

Whether you’re a manufacturer looking to optimize your paper straw production process or a business exploring the possibility of making the switch, this blog is for you. By implementing the tips and strategies discussed in this article, you can enhance your paper straw production process for the better while contributing to a more sustainable world. So, let’s dive in and discover how you can optimize your paper straw production process.

Optimizing Efficiency for straw making machine

In the production of paper straws, choosing the right straw making machine is essential to ensure efficient, cost-effective, and waste-free production. In this article, we’ll delve into the key areas of optimizing efficiency for straw making machines, including machine selection, raw material optimization, production process streamlining, and maintenance and upkeep.

Machine Selection:

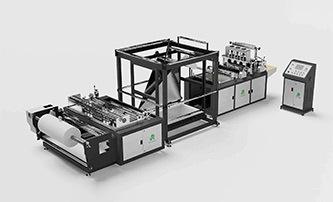

Before purchasing a straw making machine, there are key factors to consider. The machine’s capacity, capability, and design are just a few of the variables that must be analyzed to make an informed decision. Some machines may be better suited for specific straw types or raw materials, while others may offer additional functionalities like printing or bending.

It’s recommended to choose a straw machine that can handle multiple straw sizes, shapes, and thicknesses to cater to a diverse set of needs. User-friendly controls that are easy to adjust and maintain are another critical feature to consider.

Raw Material Optimization:

The quality of raw materials is just as critical as the machine itself. Paper is the primary material used in the production of paper straws, and proper selection and optimization can have significant implications for the production process’s efficiency.

Optimizing the paper type, thickness, and length is essential to ensure optimal performance from the straw making machine. Specifically, choosing the right paper quality that’s both biodegradable and safe for use in manufacturing is key to sustainability.

Production Process Streamlining:

Streamlining the production process is another critical aspect of optimizing efficiency for straw making machines. A well-designed process from start to finish will lead to higher output production lines, improved product quality, and reduced waste.

One key factor in streamlining production is implementing automation technologies like mechanical handling and packing systems. Automation technology not only enhances production speed but also minimizes labor costs while improving productivity.

Additionally, implementing a real-time quality control system can prevent production backups by ensuring that quality standards are being met and detecting errors in near real-time. Proper training for production line staff is another vital aspect of streamlining the production process.

Maintenance and Upkeep:

Optimizing efficiency also requires proper maintenance and upkeep. Regular machine diagnostics must be conducted to detect and address faults before they lead to critical failures.

Routine cleaning and preventive maintenance are other critical components of machine upkeep. Lubrication of machine parts, alignment of belts, and pulleys, and calibration of sensors and controls are all tasks that must be performed at predetermined intervals to maximize machine performance.

Finally, regular inspection of machine parts and component replacements is necessary to ensure that the machine is always operating at peak capacity. Regular inspections can identify components that may wear out prematurely, causing slowdowns or stoppages in the production process.

Cost-Saving Strategies for Your Paper Straw Making Machine:

Making the shift to paper straws from plastic necessitates cost-effective and sustainable manufacturing practices. In this article, we’ll explore practical cost-saving strategies for paper straw makers. Specifically, we’ll examine key areas of bulk purchasing, energy efficiency, waste reduction, and labor optimization.

Bulk Purchasing:

Bulk purchasing of raw materials for paper straw production is an effective cost-saving strategy. By buying in larger quantities, the unit costs of raw materials like paper, glue, and ink are reduced. This approach is used to deliver built-in economies of scale that translate to lower overall production costs for your business.

Bulk purchasing also ensures a steady supply of materials, which in turn allows you to take advantage of price discounts from your suppliers. As such, proper inventory management is vital to make the most of bulk purchasing opportunities.

Energy Efficiency:

Energy consumption can account for a significant proportion of production costs. However, energy-efficient paper straw machines, coupled with sustainable manufacturing processes, can significantly reduce your energy consumption.

Using energy-efficient machinery and technology could lead to savings from production’s first day, and could substantially reduce the production costs over time. Such machines not only reduce power consumption, but they also reduce heat generated during operations, ensuring that the machines operate under optimal conditions.

Additionally, investing in energy-efficient building designs and practices, such as natural ventilation and efficient lighting, amongst others, can deliver even further reductions in energy usage.

Waste Reduction Strategies:

Waste minimization is an essential aspect of cost-saving strategies for paper straw production processes. Through waste minimization strategies, businesses can reduce waste, lower material consumption, and save money.

Implementing a recycling program for production waste is one practical cost-saving strategy. The program optimizes paper straw production by reducing the amount of raw materials consumed, while also reducing disposal costs.

Preventing waste in the first place is another key strategy for reducing production costs further. Such strategies may include fabricating materials that can be reused, reducing the number of parts involved in the manufacturing process, or re-purposing secondary waste generated during production.

Labor Optimization:

Optimizing labor in the manufacturing process is vital for cost savings for paper straw makers. Time optimization helps reduce labor cost, which can significantly cut down production costs.

Automation is at the heart of labor optimization and is a practical cost-saving strategy that you should consider. Automating the production line tasks like filling tubes, cutting, and shaping can lead to an increase in production rates while cutting down on labor costs.

Employee training is another important aspect of labor optimization. Proper training should be provided to production line staff, especially around the safe use of machinery and in preserving raw material integrity.

Minimizing Waste

The paper straw industry has seen unprecedented growth in recent years and is poised to continue its expansion as consumer demand for sustainable options continues to rise. One common challenge that many businesses face as they navigate the industry is minimizing waste. This trend towards sustainable and environmentally friendly manufacturing processes cannot occur at the expense of waste reduction. In this article, we’ll examine practical strategies to help minimize waste in the paper straw industry. Specifically, we’ll explore recycling and upcycling, investing in eco-friendly materials, designing for minimal waste, and partnering with waste management companies.

Recycling and Upcycling:

Recycling and upcycling are excellent waste reduction strategies in the paper straw industry. Recycling involves the recovery and processing of materials that would otherwise go to waste, ensuring that the materials remain in circulation. Through recycling, it’s possible to reduce the amount of raw materials consumed while also minimizing landfill waste.

Upcycling, on the other hand, involves converting waste materials into useful products. It presents an innovative approach to minimize waste, reduce consumption of raw materials, and cut down on manufacturing costs. In the paper straw industry, upcycling may involve using recycled paper to create new and useful products.

Investing in Eco-Friendly Materials:

Apart from upcycling and recycling, investing in eco-friendly materials is another effective waste reduction strategy. Eco-friendly materials include biodegradable plastic, recycled paper, wheat straw, and bamboo amongst several others.

By selecting eco-friendly raw materials, businesses can cut down on manufacturing waste and also make significant contributions towards sustainability. As an example, paper straws made from sustainable sources can be manufactured in such a way they can be safely disposed of without impacting the environment.

Design for Minimal Waste:

Designing for minimal waste is another means of reducing production waste in the paper straw industry. This approach involves optimizing the manufacturing process for efficiency, with minimum waste generation as a central focus.

One aspect of designing for minimal waste involves ensuring that raw materials are optimized to reduce waste generation. Additionally, designing product components that are not only recyclable but also those that can be reused could result in not only cost savings but also reduced environmental impact.

Partnering with Waste Management Companies:

Partnering with waste management companies is another actionable strategy for waste reduction in the paper straw industry. Waste management companies specialize in minimizing waste, promoting recycling and upcycling, and aiming for sustainable outcomes.

Partnering with such companies creates an avenue for paper straw manufacturers to manage their waste more efficiently. Furthermore, building a sustainable relationship with waste management companies will ensure that adequate resources are directed toward attaining zero waste goals.

Conclusion

By implementing the discussed strategies into your production process, you can make the most of the growing momentum of environmentally friendly and sustainable practices. Take the first step today by reviewing your production process and implementing the tips and strategies shared in this article.

So what are you waiting for? Optimizing your paper straw making machine operation is a win-win for your business and the environment. Contact Five Fingers Exports today to learn more about our drinking straw making machines and how we can help you achieve your sustainability goals, reduce costs, and improve efficiency. Together, let’s make the world a cleaner, greener place!

Get Started with a Free Price Quote