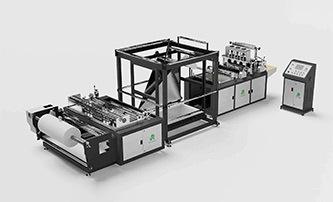

Key Considerations for Choosing the Right Paper Bag Manufacturing Machine

The Rise of Paper Bags in Packaging: A Sustainable Choice

In the contemporary era, paper bags have established themselves as an essential component of the packaging sector. Whether in modest enterprises or upscale establishments, paper bags have replaced plastic bags as the preferred eco-friendly packaging option. With the rising concern over plastic pollution, the demand for paper bags has surged, prompting manufacturers to seek out the best paper bag-making machines to enhance their production capabilities.

If you’re considering entering the paper bag manufacturing business or looking to upgrade your existing equipment, it’s crucial to understand the specifications and features that matter most. In this blog, we’ll walk you through the essential parameters to consider when selecting the ideal paper bag machine.

Automatic monitoring mechanisms:

Investing in a machine with automatic control systems can significantly boost the efficiency of your production unit. With automated processes for gathering, folding, cutting, sealing, stacking, and conveying, you can streamline your operations and maintain high-quality paper bag production. Features such as PLC control, frequency-controlled speed adjustment, and a remote control system are must-haves. These functionalities ensure that side gluing, gusset shaping, base folding and pasting, automatic collection, and counting are all seamlessly integrated into one continuous operation.

Bag Dimensions:

Customers have varying specifications for their paper bags, ranging in size, shape, and color. To meet diverse market demands and stay competitive, your bag-making machine should be adaptable. Look for a machine that allows you to manufacture bags of different sizes and styles with ease by making simple adjustments to their gears.

Speed Control:

Efficiency is key in the manufacturing industry. Ensure that the machine you choose operates at the correct speed to meet your production requirements. There are two types of speed to consider:

- The host speed (the machine’s set speed)

- The machine’s actual speed (the speed at which it operates).

It’s essential to select a machine that aligns with your manufacturing process’s speed needs.

Bags’ Design:

Paper bags are increasingly used as a branding tool for businesses. The design and appearance of these bags can leave a lasting impression on customers. Therefore, it’s essential to check if the machine you’re considering can produce a variety of bag designs. Customization options are vital for businesses looking to create unique and branded paper bags.

Marking Features:

Paper bags often feature imprinted markings, such as the manufacturer’s name, country of origin, bag size indicators, and more. Ensure that the machine you choose can accurately print this information on the bags once the manufacturing process is complete. The bags should be free from defects such as dust, holes, or splinters.

Gumming with Accuracy:

The sealing of the bottom ends of paper bags is crucial to ensure they remain secure and intact. Choose a machine that evenly applies gum or adhesive along the entire length of the seam during bag creation. This meticulous process results in a perfect closure, enhancing the overall quality of your paper bags.

Summing Up:

In summary, investing in the right paper bag manufacturing machine with the appropriate features can significantly increase your production efficiency. Automatic functionalities streamline your processes, while the ability to customize bag dimensions and designs ensures you can meet diverse customer demands. By carefully considering these factors, you can save on production costs, meet project deadlines, and stay ahead of your competitors in the paper bag manufacturing industry. Make a sustainable choice and contribute to a cleaner planet with high-quality paper bags.

Get Started with a Free Price Quote