Is Single-Pass Printing the Answer to Diverse Industry Needs?

Revolutionizing Production: The Impact of Single-Pass Printing on Manufacturing

In the ever-evolving manufacturing landscape, the launch of single-pass printing technology has emerged as a ground-breaking innovation, reshaping the production processes across various industries. This cutting-edge printing method, characterized by its ability to swiftly and accurately imprint designs on various materials in a single pass, has revolutionized the way products are manufactured.

What is Single-Pass Printing?

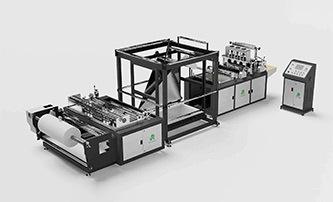

Single-pass printing is a digital printing technology that allows for high-speed printing of large volumes of material. Unlike traditional printing methods, which require multiple passes over the same area, single-pass printing can print an entire image in just one pass.

The Shift in Manufacturing Paradigms

Traditional manufacturing methods often involve time-consuming and labour-intensive processes. However, single-pass printing has significantly streamlined production, driving efficiency and quality to new heights. Its impact spans numerous industries, from textiles and packaging to 3D printing and beyond.

Speed and Efficiency Redefined

One of the most profound impacts of single-pass printing on manufacturing is the exponential increase in speed and efficiency. By enabling rapid, continuous printing in a single pass, this technology has minimized downtime and substantially reduced production timelines. Manufacturers can now produce high-quality, customized products with unmatched speed, meeting the demands of an increasingly fast-paced market.

Customization and Personalization

The era of mass production is being replaced by a demand for customization and personalization. Single-pass printing facilitates this shift by allowing manufacturers to easily tailor each product to individual preferences. This flexibility has led to a surge in the production of personalized items, be it custom-designed apparel, unique packaging, or individualized 3D-printed products.

Resource Optimization and Sustainability

Moreover, the impact of single-pass printing on resource optimization and sustainability cannot be understated. By reducing material wastage and energy consumption compared to traditional printing methods, this technology aligns with the global push towards sustainable manufacturing. It not only minimizes environmental impact but also results in cost savings for manufacturers.

Adaptability across Industries

The versatility of single-pass printing is another factor driving its impact on manufacturing. Its applications span across various sectors, from fashion and consumer goods to industrial and automotive manufacturing. This adaptability showcases the far-reaching influence of single-pass printing in optimizing and improving production processes across diverse industries.

Challenges and Future Outlook

While single-pass printing has brought about significant advancements, it also faces challenges that require continual innovation. Precision, colour consistency, and material compatibility are areas where on-going developments are vital. As technology advances, the future outlook is promising, with a focus on enhancing speed, and resolution and expanding the range of printable materials.

Examples of Single-Pass Printing in Manufacturing

The utilization of single-pass printing has already found application in various industries, including but not limited to the following:

- Textile Printing: Single-pass printing stands as an invaluable asset in the realm of textile printing. This technology has demonstrated its capability to markedly decrease production timelines and associated costs. Numerous textile manufacturers are actively integrating this technology into their production processes to streamline and enhance their operations.

- Industrial Printing: Beyond textile applications, single-pass printing has extended its reach into industrial printing. Industries rely on this technology for various purposes, particularly in the printing of packaging materials. Its efficiency and precision in printing onto packaging materials have made it a preferred choice in this sector, offering high-quality and swift solutions for packaging requirements.

- Automotive and Custom Product Manufacturing: Furthermore, it has gained ground in automotive manufacturing and the creation of custom products. Its versatility in rapidly and accurately printing designs onto various materials has facilitated its use in the production of customized automotive parts and a diverse array of personalized products.

- Medical and Electronics Sectors: The medical and electronics sectors have also recognized the potential of single-pass printing. This technology’s precision and speed are advantageous in the production of intricate electronic components and the customization of medical devices, fostering the development of innovative solutions within these industries.

Conclusion

In conclusion, the impact of single-pass printing on manufacturing is transformative. Its ability to enhance speed, customization, and sustainability while streamlining production processes across industries underscores its significance in shaping the future of manufacturing. As this technology continues to evolve, its potential to revolutionize production and drive innovation remains both compelling and exciting.

Get Started with a Free Price Quote